Improving Tote Filling Efficiency with a Custom Vibratory Weighing System

Improving Tote Filling Efficiency with a Custom Vibratory Scale

One of our partners was having trouble filling large totes with plastic pellets. The pellets created static and clumped together, which caused them to stack unevenly inside the container. As a result, totes often appeared full or overflow long before reaching the correct weight. Operators had to manually shake or shift the totes to settle the material. This process was slow, physically demanding, and inconsistent. It also put strain on the scale system because standard load cells are not designed for that kind of movement.

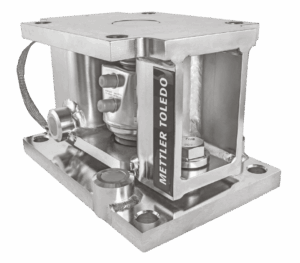

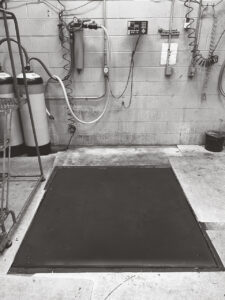

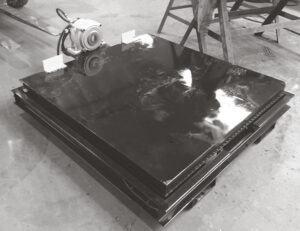

To support a smoother and more efficient filling process, the System Scale team designed a custom vibratory scale built specifically for this application. The system allows the tote to be filled to a preset weight, then automatically pauses the feed and activates a controlled shaking cycle to help the pellets settle. Once the material levels out, the feeder restarts and continues the filling sequence. The process repeats at several programmed set points until the final target weight is reached. Because the scales were engineered to handle vibration, they avoid the damage that would occur with standard weigh systems.

After testing a few units, our partner saw significant improvements in consistency and throughput. The totes filled more evenly, operators no longer had to manually shake containers, and the risk of overflow was eliminated. The success of the initial units led the partner to purchase a full fleet to support multiple production lines.

The custom vibratory scale solution now provides a reliable, efficient approach to filling totes that improves speed, reduces strain on operators, and protects the weighing equipment from unnecessary wear.

Project Highlights

-

Industry:

Plastics, Material Handling -

Application:

Plastic Pellet Tote Filling -

Equipment Used:

Custom Vibratory Floor Scale, IND570 -

Challenge:

Plastic pellets clumped due to static, causing uneven filling, manual shaking, and risk of scale damage -

Results:

Faster filling, no overflows, reduced operator strain, and a full fleet of units added across multiple lines