High-Precision Counting System Improves Inventory Accuracy

Improving Counting Accuracy with a High-Precision Sample Counting System

A distributor and manufacturing facility was experiencing inconsistent part counts that affected both outgoing shipments and internal inventory control. Their quality department was exploring new bench and floor scale combinations and had worked with a local supply house to select several models based on platform size and capacity. Wanting a second opinion, they reached out to their local System Scale team. As employee-owners, we understand the importance of choosing equipment that is fit for purpose and delivers the best long-term ROI.

To ensure the recommended equipment would truly meet the demands of their counting process, the System Scale team gathered sample parts, calculated an Average Piece Weight (APW), and ran the data through a Good Weighing Practice (GWP) analysis. The results showed that the application required a higher level of precision than the originally quoted models were designed to provide. A more precise system would help ensure consistent part counts and reduce variation in their inventory process.

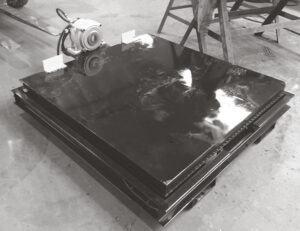

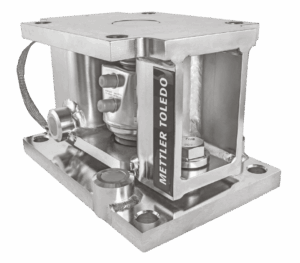

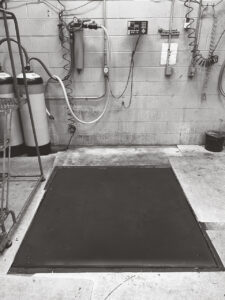

Based on the evaluation, our team recommended a dual-scale solution consisting of a high-precision ICS465 counting scale for accurate sample weighing paired with a higher-capacity PFA584 platform for larger counts. This configuration delivered the resolution and stability needed for reliable piece counting while supporting an efficient inventory workflow. The ICS465 provided fast, highly accurate sampling to establish a dependable APW, and the connected floor scale enabled efficient pallet-level counting using the precise APW generated by the high-precision bench scale.

The result was a fit-for-purpose system that improved efficiency, increased counting accuracy, strengthened inventory control, and supported more reliable order fulfillment. By focusing on process requirements rather than basic specifications, System Scale helped the partner implement a high-precision solution that performs consistently and delivers meaningful operational value over time.

Project Highlights

-

Industry:

Industrial Manufacturing & Distribution -

Application:

Precision Piece Counting / Quality Control -

Equipment Used:

ICS465 high-precision counting scale, PFA584 platform -

Challenge:

Inaccurate part counts and inadequate precision from standard bench/floor scale options -

Results:

Improved counting accuracy, better inventory control, and a tailored, process-driven solution

Need More Accurate Counting in Your Process?

If your counting or inventory checks are inconsistent, a precision-based evaluation can make all the difference. Share a few details about your workflow below, and our team will help you determine the right equipment for reliable piece counting.