Indicator Upgrade Improves Reliability and Streamlines Truck Scale Data

Modernizing a Truck Scale Indicator for Reliable Data and Future Connectivity

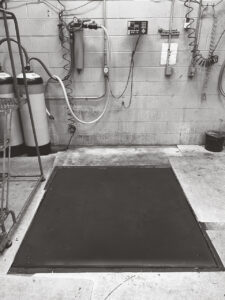

As an aggregate partner prepared to connect multiple plants through centralized order tracking, their outdated Lynx indicator became a major obstacle to reliability and future integration. The indicator had been out of production for years, and replacement parts were no longer available. Any failure would have created significant downtime and disrupted the flow of scale data the operation depended on each day.

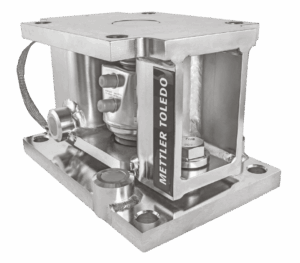

To prevent those risks and support the partner’s long-term plans, the employee-owners at System Scale recommended upgrading the truck scale to a modern IND570 terminal with Ethernet communication. The new indicator offered dependable performance for current operations and ensured compatibility with the centralized software platform they planned to roll out across multiple locations.

With the upgraded terminal in place, the truck scale now sends time, weight, company, and truck-load data directly to the partner’s systems. This reduces manual entry, improves throughput, and supports a smoother scale house workflow. The proactive upgrade eliminated the threat of extended downtime and put the partner in a strong position as their multi-plant data strategy continues to expand.

Project Highlights

-

Industry:

Aggregate -

Application:

Truck Scale Modernization / Data Connectivity -

Equipment Used:

IND570 terminal with Ethernet communication -

Challenge:

Obsolete indicator with no support, downtime risk, and need for future system integration -

Results:

Improved reliability, simplified data flow, reduced downtime risk, and future-ready connectivity

Need a More Reliable Truck Scale System?

If outdated indicators or manual data entry are slowing down your operation, a modern upgrade can improve reliability and prepare your scale for future connectivity. Share a few details below, and our team will help you find the right solution for your site.