Custom Checkweighing System Improves Kit Accuracy and Efficiency

Reducing Kit Assembly Errors with a Custom Checkweighing System

A manufacturing partner was seeing too many incomplete or incorrect kits leaving their facility. Their manual kitting process offered no reliable way to verify accuracy, which led to rework, customer complaints, and lost production time. They needed a simple, repeatable way to confirm each kit was assembled correctly before shipment.

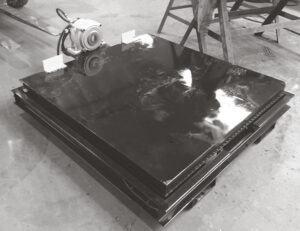

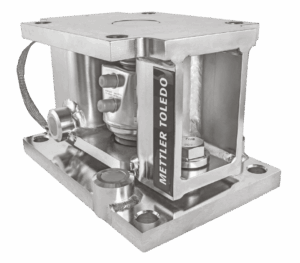

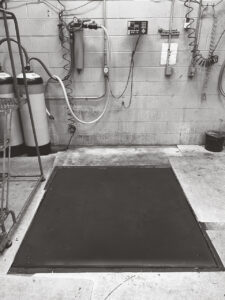

To support their workflow and reduce kitting errors, the System Scale team took time to understand how their operators built each kit. From there, we helped designed a custom checkweighing solution using Mettler Toledo weighing bases paired with Rice Lake terminals with custom programming. Operators now enter the kit number, and the terminal automatically sets a target weight and tolerance range based on the kit contents. If the kit meets those requirements, the system prints a pass label for quick traceability and quality review.

Large monitors also display reference images of the correct kit layout. This gives operators a simple visual check before placing the kit on the scale. Combining visual confirmation with weight verification created a clear and reliable process that fits the way their team works and helps reduce training time for new employees.

With the new system in place, our partner reduced assembly errors, minimized rework, and increased throughput. The solution also provides long-term consistency and supports a more dependable, easy-to-learn kitting process that improves accuracy, saves time, and creates a better experience for both operators and customers.

Project Highlights

-

Industry:

Manufacturing -

Application:

Kit Checkweighing / Quality Control -

Equipment Used:

Mettler Toledo weighing bases, Rice Lake terminals with custom programming -

Challenge:

Manual kitting errors and no verification method -

Results:

Reduced rework, improved kit accuracy, faster and more consistent production