Deciding Instrument Calibration Protocols

For those outside the metrology world, selecting a calibration procedure may feel overwhelming. To make things a little easier, we’ve put together a quick guide that explains the basics of calibration and the factors that go into choosing the correct process for your equipment. While there’s no one-size-fits-all solution, this guide will walk you through the decision-making process.1. Check for Existing Procedures or Regulations

When determining if equipment requires calibration, your first step should be reviewing any existing procedures, customer contracts, or regulations that define calibration requirements. These established quality procedures should serve as the minimum standard for your calibration needs. If no procedures exist, or if you are working to define them, continue to the steps below.

Although there are countless procedures, regulations, and standards, the two most common requirements are ISO/IEC 17025 accreditation and Handbook 44:- ISO/IEC 17025 – This accreditation doesn’t define a step-by-step procedure. Instead, it confirms that a calibration laboratory operates under a rigorous quality system and has the technical skill to provide accurate, repeatable results. Many industries (and quality systems like ISO 9001) require the use of ISO/IEC 17025 accredited labs.

- Handbook 44 – Unlike ISO/IEC 17025, Handbook 44 is far more prescriptive. Issued by NIST, this standard lays out specific test points and tolerances for scales. If your scale is used in a legal-for-trade setting (determining price or amount being bought or sold), Handbook 44 compliance is often a legal requirement.

2. Determine if a Measurement is Made or Used

Since all measurement equipment drifts over time, the general rule of thumb is simple: if it measures, it needs calibration. Identifying measurement equipment may sound straightforward, but not all equipment uses measurements in the same way.

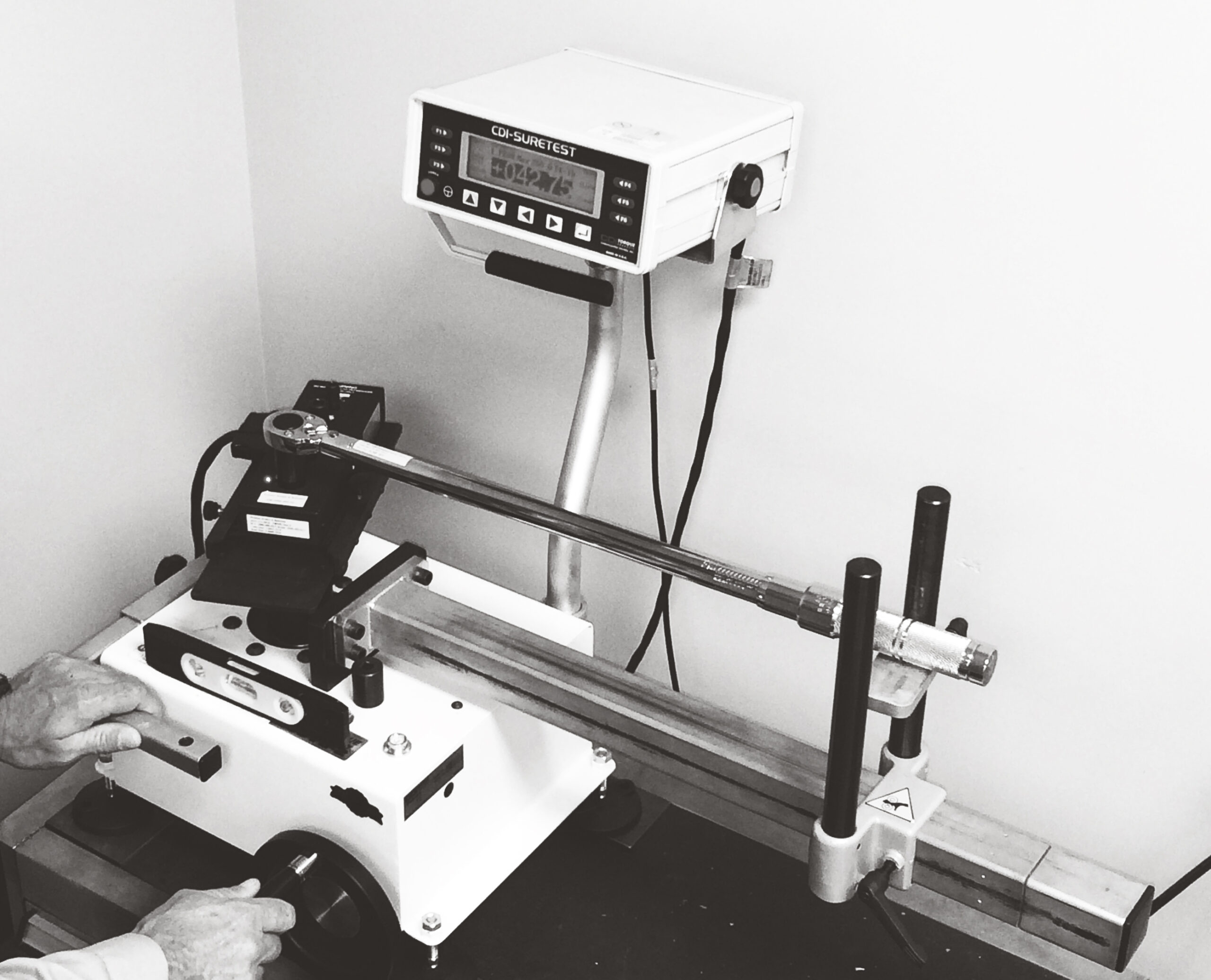

Direct Measurement Devices – This is the most obvious category. Tools like calipers, multimeters, and scales that are measuring a value and give you a result.

Reference Standards & Artifacts – This category may not display numbers but it does serve as the reference point that other equipment is compared against. Examples include check weights, gage blocks, and thread gauges. It may surprise you, but even these reference items change slightly with wear, handling, or environmental conditions. Without regular calibration, their reliability fades, and every measurement taken against them becomes questionable.

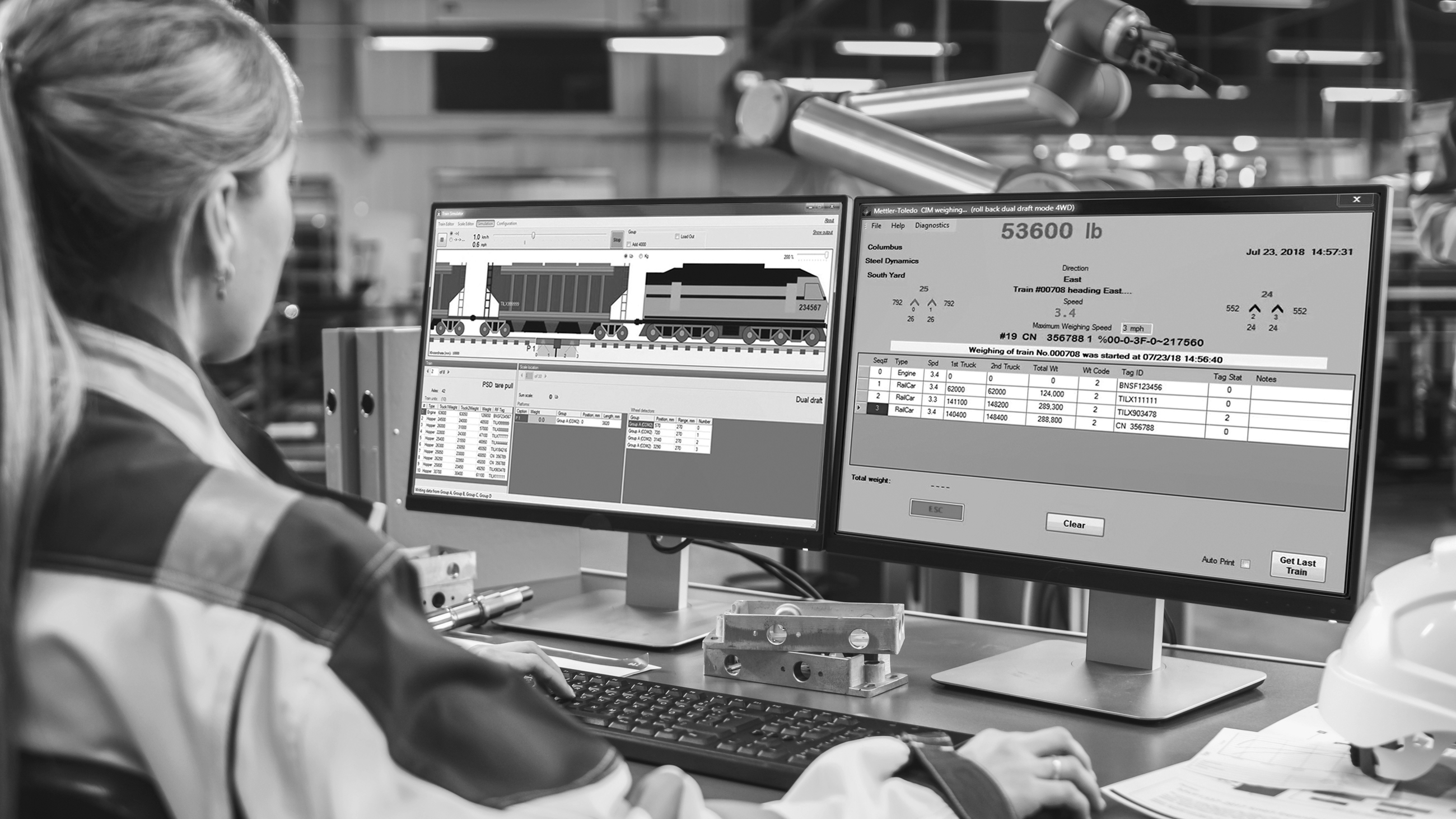

Hidden Measurements in Automated Systems – Modern processes often take measurements behind the scenes. Automated equipment and safety systems often rely on preset values, called set points, to trigger actions. Even though an operator never sees the numbers, those hidden measurements still drift and need calibration to keep the process safe and accurate.

The Exception – There is one exception: if equipment is used only to indicate a general condition where the precise measurement doesn’t matter, calibration may not be necessary. Examples include a pressure gauge used only to confirm whether a vessel is pressurized, or a multimeter used only to check for the presence of electricity. In these cases, a regular verification is still recommended to ensure functionality. We also recommend all non-calibrated equipment should be clearly labeled to avoid confusion.

Since all measurement equipment drifts over time, the general rule of thumb is simple: if it measures, it needs calibration. Identifying measurement equipment may sound straightforward, but not all equipment uses measurements in the same way.

Direct Measurement Devices – This is the most obvious category. Tools like calipers, multimeters, and scales that are measuring a value and give you a result.

Reference Standards & Artifacts – This category may not display numbers but it does serve as the reference point that other equipment is compared against. Examples include check weights, gage blocks, and thread gauges. It may surprise you, but even these reference items change slightly with wear, handling, or environmental conditions. Without regular calibration, their reliability fades, and every measurement taken against them becomes questionable.

Hidden Measurements in Automated Systems – Modern processes often take measurements behind the scenes. Automated equipment and safety systems often rely on preset values, called set points, to trigger actions. Even though an operator never sees the numbers, those hidden measurements still drift and need calibration to keep the process safe and accurate.

The Exception – There is one exception: if equipment is used only to indicate a general condition where the precise measurement doesn’t matter, calibration may not be necessary. Examples include a pressure gauge used only to confirm whether a vessel is pressurized, or a multimeter used only to check for the presence of electricity. In these cases, a regular verification is still recommended to ensure functionality. We also recommend all non-calibrated equipment should be clearly labeled to avoid confusion.