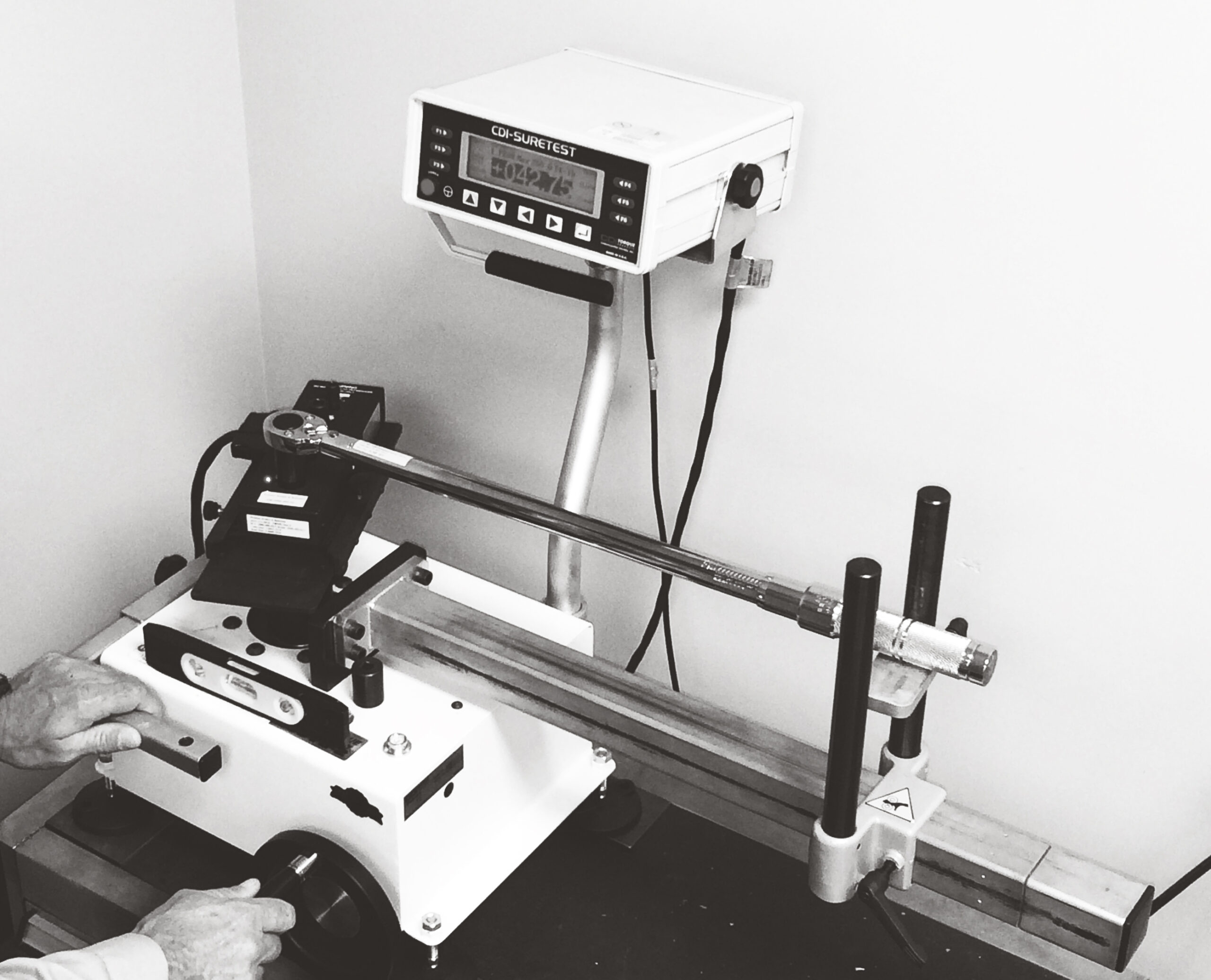

More than a Chunk of Granite

Surface plates may seem no different than any other working surfaces, but they are actually precision instruments. Despite granite’s toughness and durability, continual use will ultimately create wear spots on the surface. These seemingly tiny surface variations can cause distortions in measurements and ultimately affect product quality. Over the years System Scale has sold and serviced numerous surface plates. Although wear is unavoidable, our experience has taught us a lot about how proper care and maintenance can extend your surface plate’s life and accuracy.

Surface plates may seem no different than any other working surfaces, but they are actually precision instruments. Despite granite’s toughness and durability, continual use will ultimately create wear spots on the surface. These seemingly tiny surface variations can cause distortions in measurements and ultimately affect product quality. Over the years System Scale has sold and serviced numerous surface plates. Although wear is unavoidable, our experience has taught us a lot about how proper care and maintenance can extend your surface plate’s life and accuracy.