Your Guide to Reliable Weighing

Accurate weighing starts with well-maintained equipment. Over time, everyday factors like dust, debris, vibration, moisture, and normal wear can affect how your scales perform. Even small changes can lead to inconsistent readings, impacting efficiency, quality control, and compliance.

That’s why regular maintenance is key. Whether you rely on truck scales, bench scales, floor scales, hopper systems, or lab balances, a proactive upkeep routine keeps your operation running smoothly and your results reliable. Use this checklist as a quick guide to help you spot issues early, prevent downtime, and ensure every weigh is a correct one.

Regular inspection and calibration services help you:

- Catch early signs of wear before they become downtown

- Maintain compliance with industry and safety standards

- Ensure every weighing result is reliable and precise to reduce rework costs

Your Scale Maintenance Checklist

Here are a few areas to focus on as part of your preventative maintenance program.

Common Issues:

Over time, moisture, dust, and temperature fluctuations can cause buildup or corrosion that interferes with scale performance.

Debris:

Clean away dirt, mud, or buildup from around the base to ensure debris is not interfering with the scale components.

Foundation or Platform:

Inspect the surface and surrounding area for cracks or uneven wear that could affect weighing accuracy. Clean away dirt, mud, or buildup from around the base.

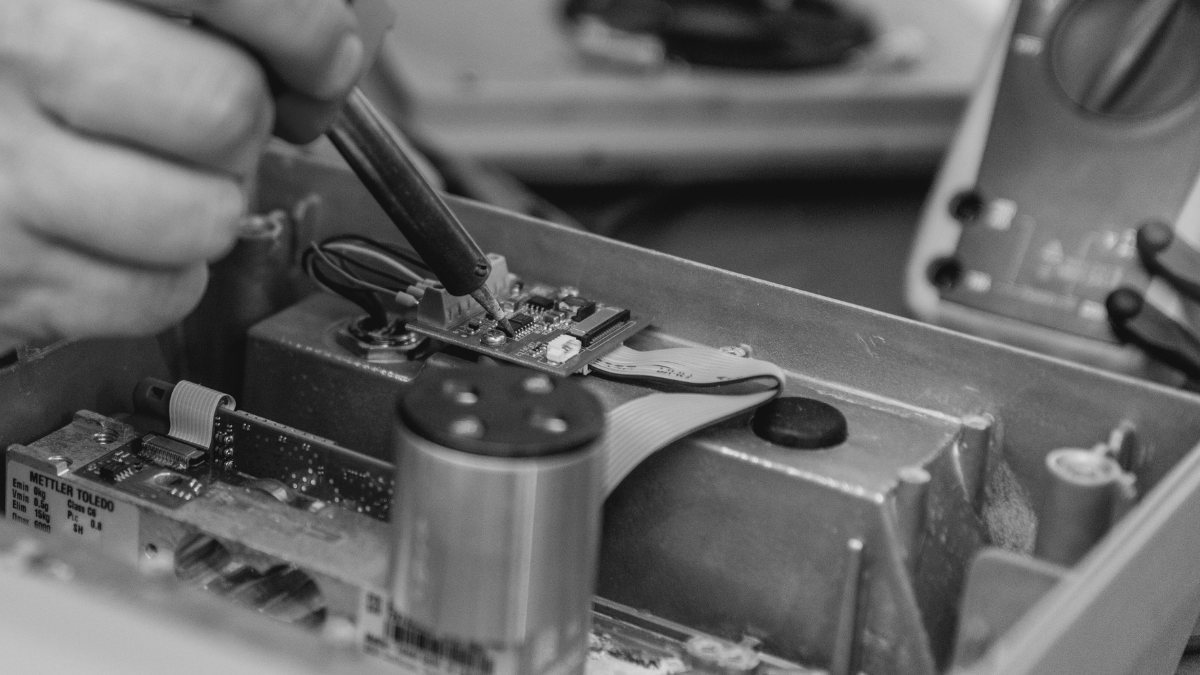

Load Cells:

Visually check for frayed or corroded cables, moisture damage, or rodent activity. Ensure grounding and lightning protection systems are secure and functional.

Junction Boxes:

Confirm that lids are sealed, boxes are properly fastened, and no water or debris has entered. Moisture in junction boxes is a common cause of calibration drift.

Mechanical Components:

Look for corrosion, worn bolts, or excessive movement. Keep moving parts clean and lubricated according to manufacturer recommendations.

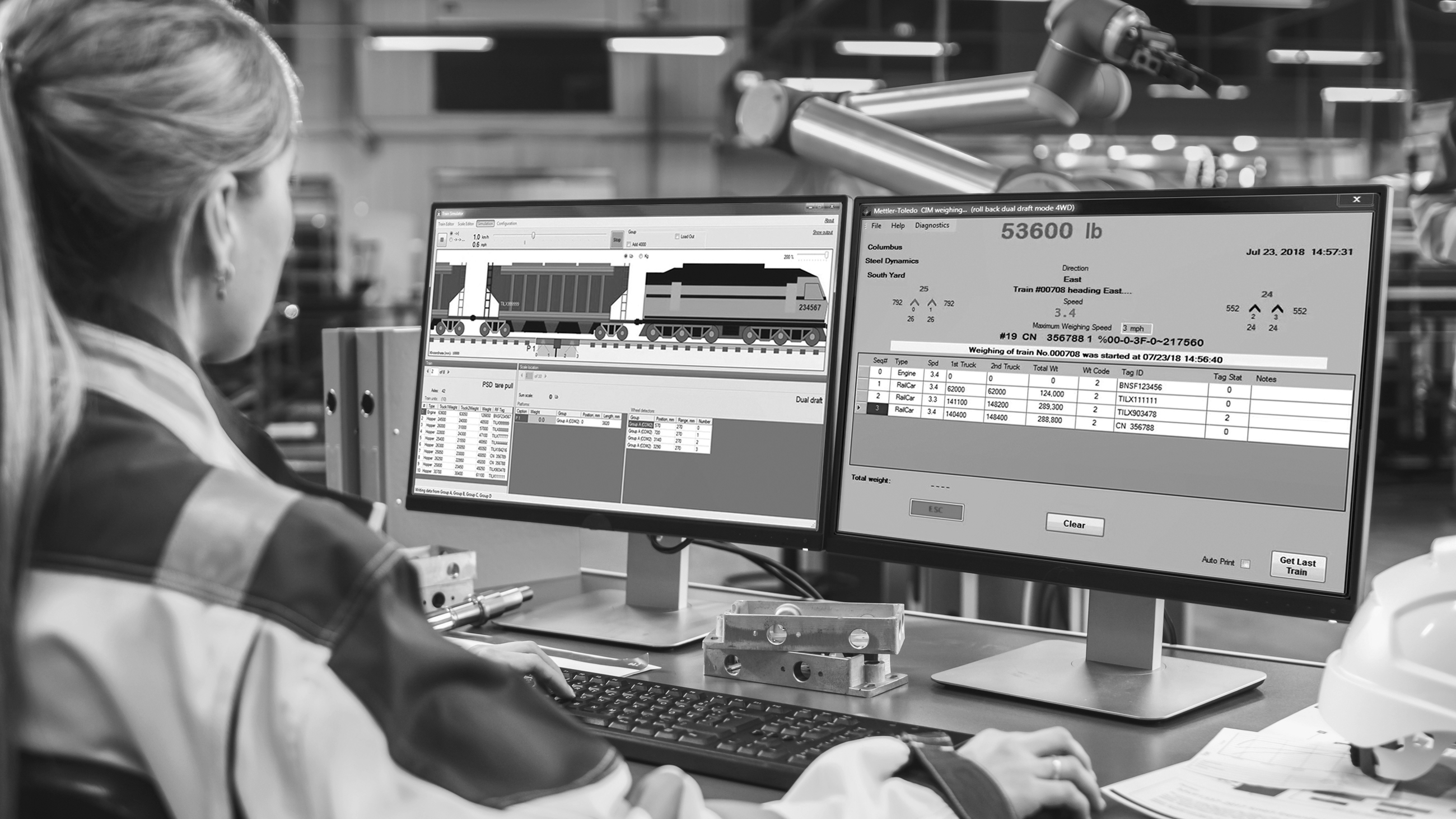

Indicators and Printers:

Clean dirt and dust from terminals to prevent overheating. Verify that all buttons and zero functions work correctly and that readings stabilize quickly.

Don’t forget to check your calibration sticker. If it’s out of date, or if you’ve noticed changes in performance, it’s time to schedule a scale calibration service.

Ready to schedule your service?

Call your local System Scale office or fill out the form below to schedule a consultation.