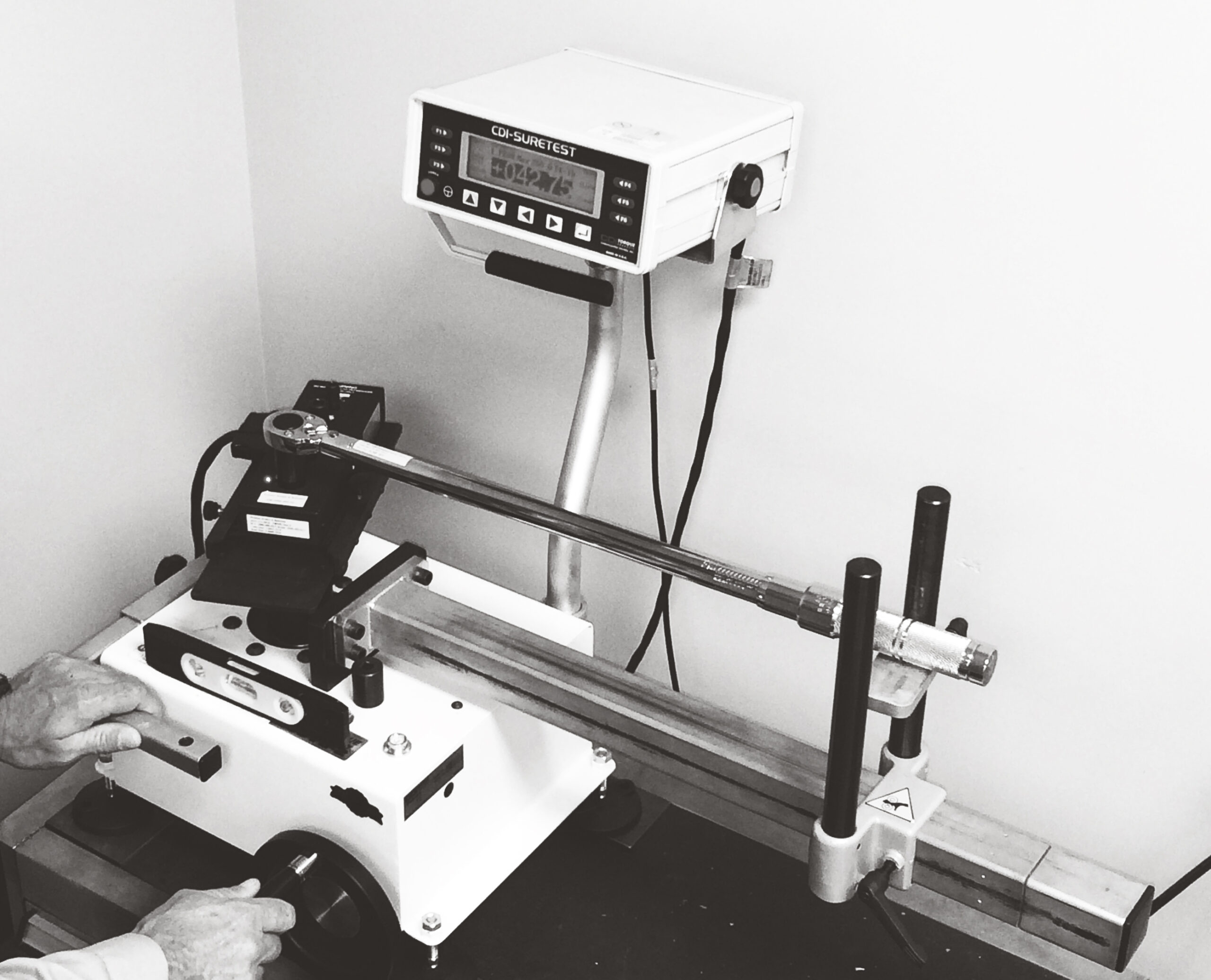

“Is the scale calibrated?”

Many teams assume calibration ensures measurement accuracy. In reality, calibration verifies performance at a specific point in time, but true measurement accuracy depends on the entire system surrounding the equipment.

The shortcut makes sense. Certificates are visible. Stickers are current. Documentation is filed.

On the surface, everything appears compliant. But accuracy is not a sticker. Accuracy is a system.

In busy operations, accuracy can easily become a periodic check rather than a continuously observed system. When that happens, risk doesn’t disappear. It simply becomes harder to see.

Accuracy, Precision, and Trueness Are Not Interchangeable

The word “accuracy” is often used loosely, but measurement performance is more than that.

Accuracy describes how close a measurement is to the true value.

Precision describes repeatability, whether the same input produces the same result.

Trueness reflects whether results are unbiased over time.

A device can be highly precise yet consistently wrong. It can be accurate during calibration, then influenced by its operating environment. It can meet specification on paper while slowly drifting in practice.

Those differences matter across your operation.

- Quality teams see it in audit readiness.

- Maintenance leaders see it in stability and troubleshooting.

- Executives see it in cost control and operational risk.

Understanding the difference is not about passing a test. It is foundational to controlling measurement performance.

Measurement Performance Extends Beyond the Equipment

A scale may pass calibration today. But if throughput increases, traffic patterns change, or environmental stress accelerates wear, performance can shift between intervals.

By the time the issue surfaces, it may show up as rejected product, a disputed shipment, unexplained yield loss, or downtime.

The hardware didn’t fail. The surrounding conditions changed. And without full-system visibility, those shifts are easy to miss.

The Risk of Treating Accuracy as a Checkbox

In many facilities, measurement control is structured around scheduled intervals. Those intervals are essential, but they only provide a snapshot in time.

Between those checkpoints, usage patterns can change. Environmental stress accumulates. Small shifts begin to develop.

The equipment may still carry a valid certificate. The process, however, may not be performing as consistently as expected.

By the time the issue becomes visible, it’s rarely visible at the scale. It shows up in quality metrics, production output, or audit findings.

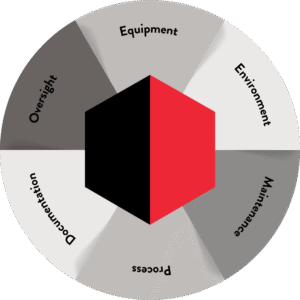

What It Means to Manage Accuracy as a System

Calibration is part of the equation. So is maintenance. So is traceability. None of those elements stand alone. Accuracy is a system.

At System Scale, we approach measurement with that full-system mindset. We don’t just look at certificates or intervals. We look at how equipment fits into your operation and how it’s installed, used, maintained, and supported over time.

Because protecting measurement integrity isn’t about pointing out gaps. It’s about working alongside your team to keep the entire process aligned.

When accuracy is managed as a system, everyone benefits, from the plant floor to the board room.