A Global System Built on Precision

Today’s supply chains rely on countless moving parts, literally. Components made in different states, countries, and continents must fit together flawlessly. A bolt manufactured in Kentucky might be installed in machinery assembled in Mexico using parts designed in Japan.

Despite the complexity, everything aligns. That is not something that happens by accident. It is because the world runs on shared measurement standards that keep every dimension, every tolerance, and every part speaking the same “language.”

That shared language comes from one critical concept: measurement traceability.

Calibration Alone Cannot Guarantee Compatibility

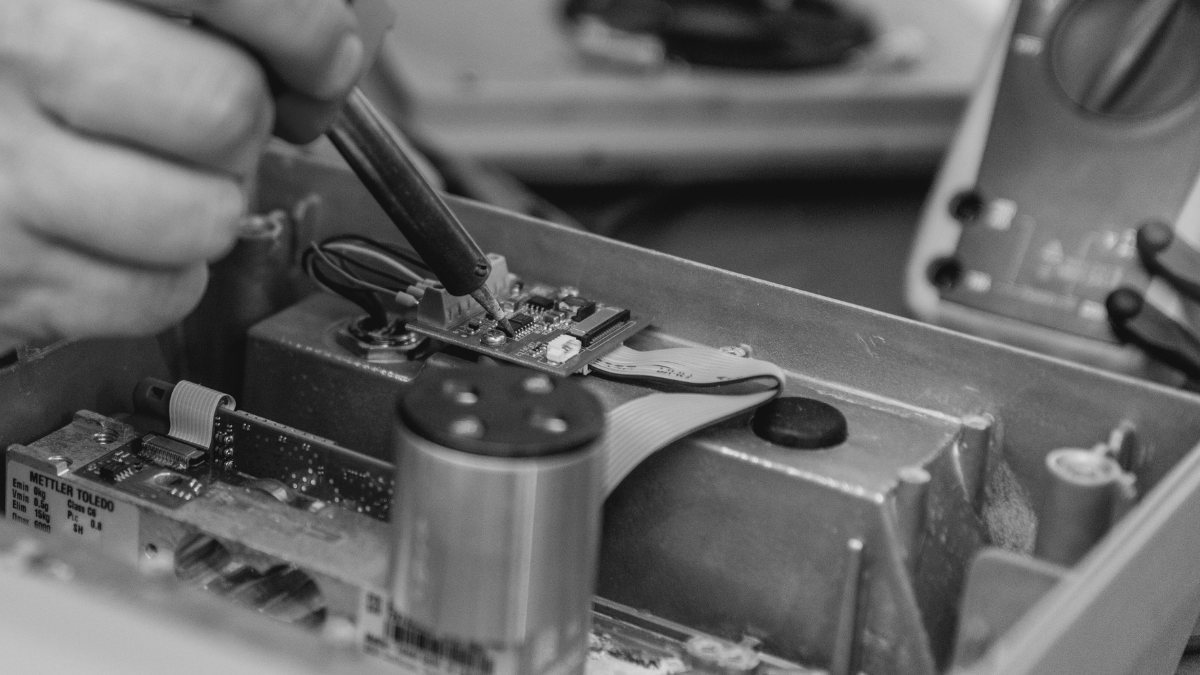

Calibration compares a measurement device to a known standard. But without a way to connect that standard to a universal reference, you end up with isolated pockets of accuracy.

A bolt calibrated to a Kentucky standard does not automatically fit a part produced in Japan unless both standards ultimately trace back to the same internationally recognized source.

That is where traceability becomes essential.

Understanding the Traceability Chain

If you have ever reviewed a calibration certificate, you have likely seen a section listing traceability information. Those numbers are not just administrative details. They are the chain that links your equipment to recognized national and international standards.

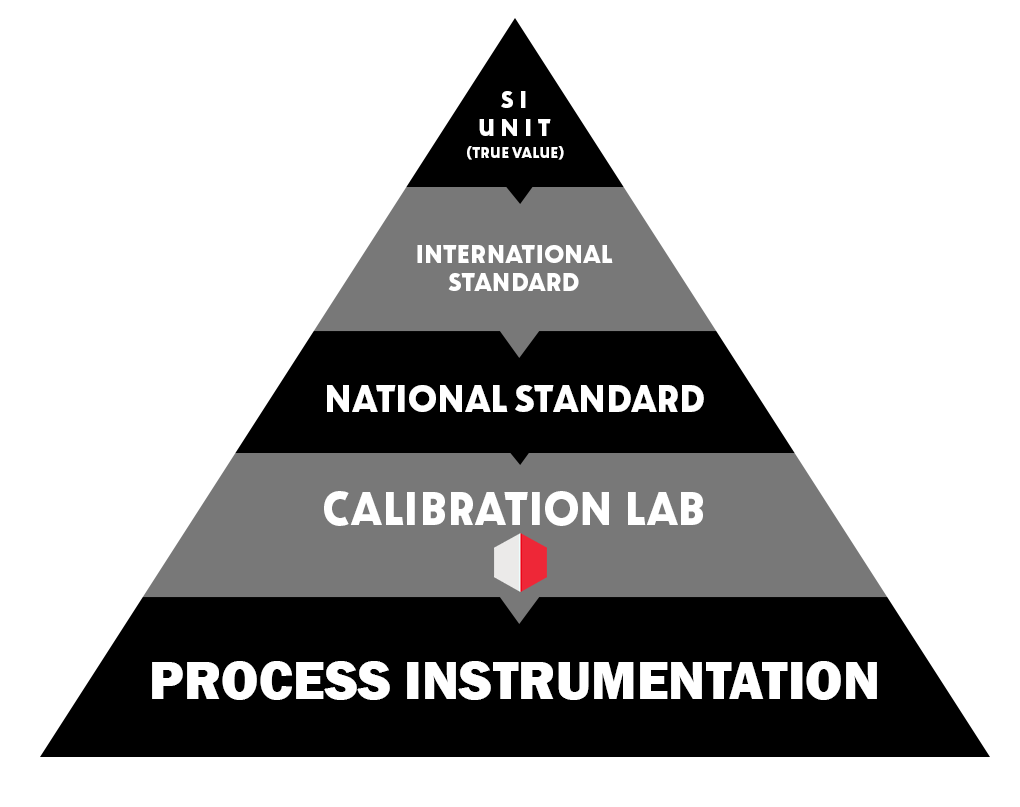

Here is how the traceability chain works:

-

Your equipment is calibrated using a verified reference standard in an accredited lab.

-

That reference standard is certified and documented, with traceability to higher-level reference standards.

-

Those higher-level standards are maintained under progressively tighter controls and lower measurement uncertainty.

-

At the top of the chain are the seven SI units, which serve as the globally recognized definitions for all measured values.

Each step up the chain provides tighter tolerances, lower measurement uncertainty, and universally comparable results. That is the reason an M8 bolt made in Kentucky will fit any properly manufactured M8 hole anywhere in the world.

How System Scale Strengthens Your Traceability Program

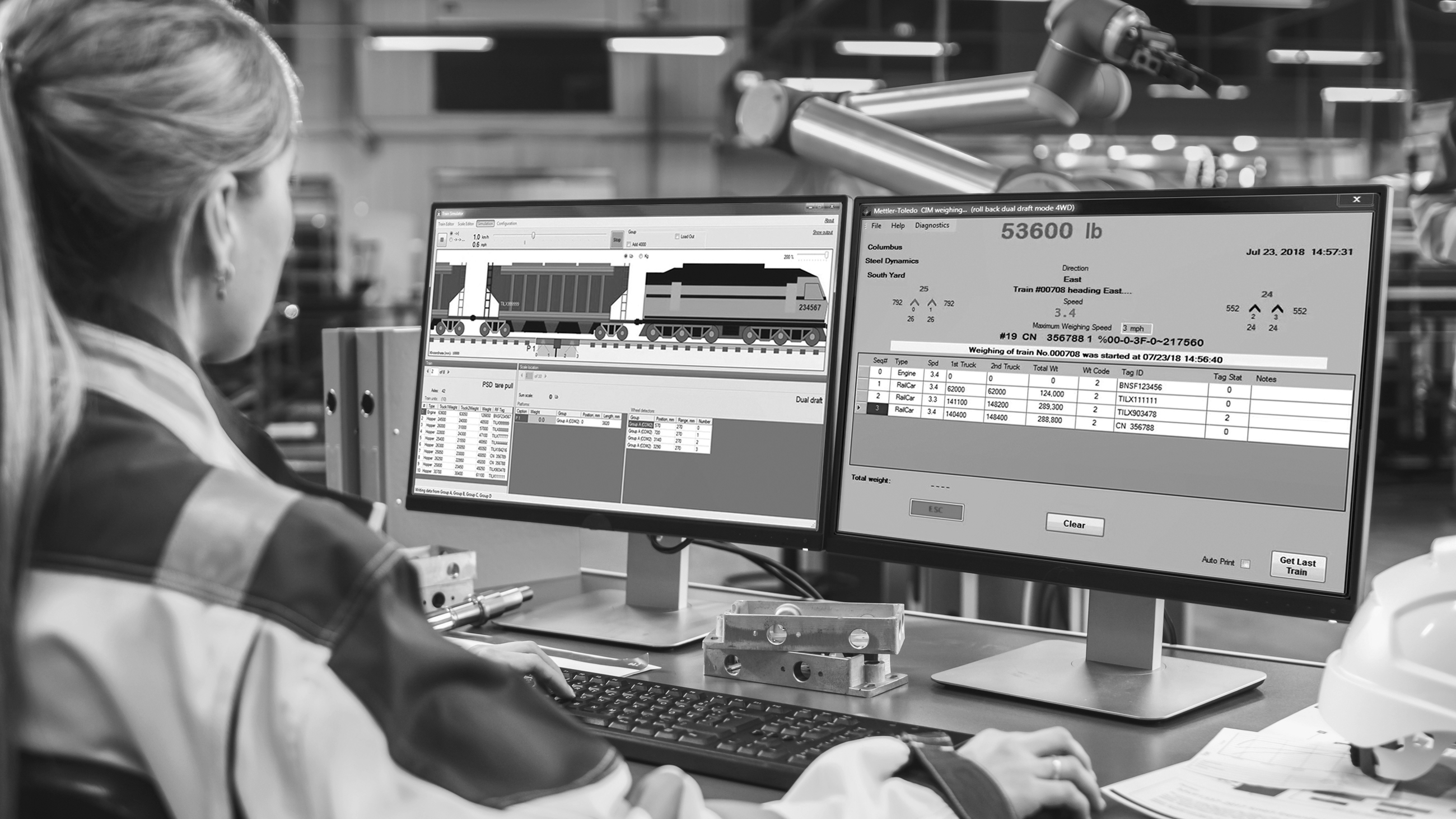

As a full-service ISO/IEC 17025 accredited calibration provider, System Scale ensures your measurements are accurate, compliant, and traceable.

What that means for your operation:

- One partner for all metrology needs including scales, instruments, force, torque, pressure, temperature, and more

- Employee-owned accountability ensuring every team member is invested in your uptime

- Simplified documentation and record management, with optional CalVault access for secure, centralized visibility into calibration certificates, asset records. and invoicing

Strengthen Your Measurement Program with Confidence

Whether you are trying to reduce uncertainty, simplify audits, or consolidate vendors, our team is ready to help.

Request a quote today and let System Scale reinforce your traceability chain.