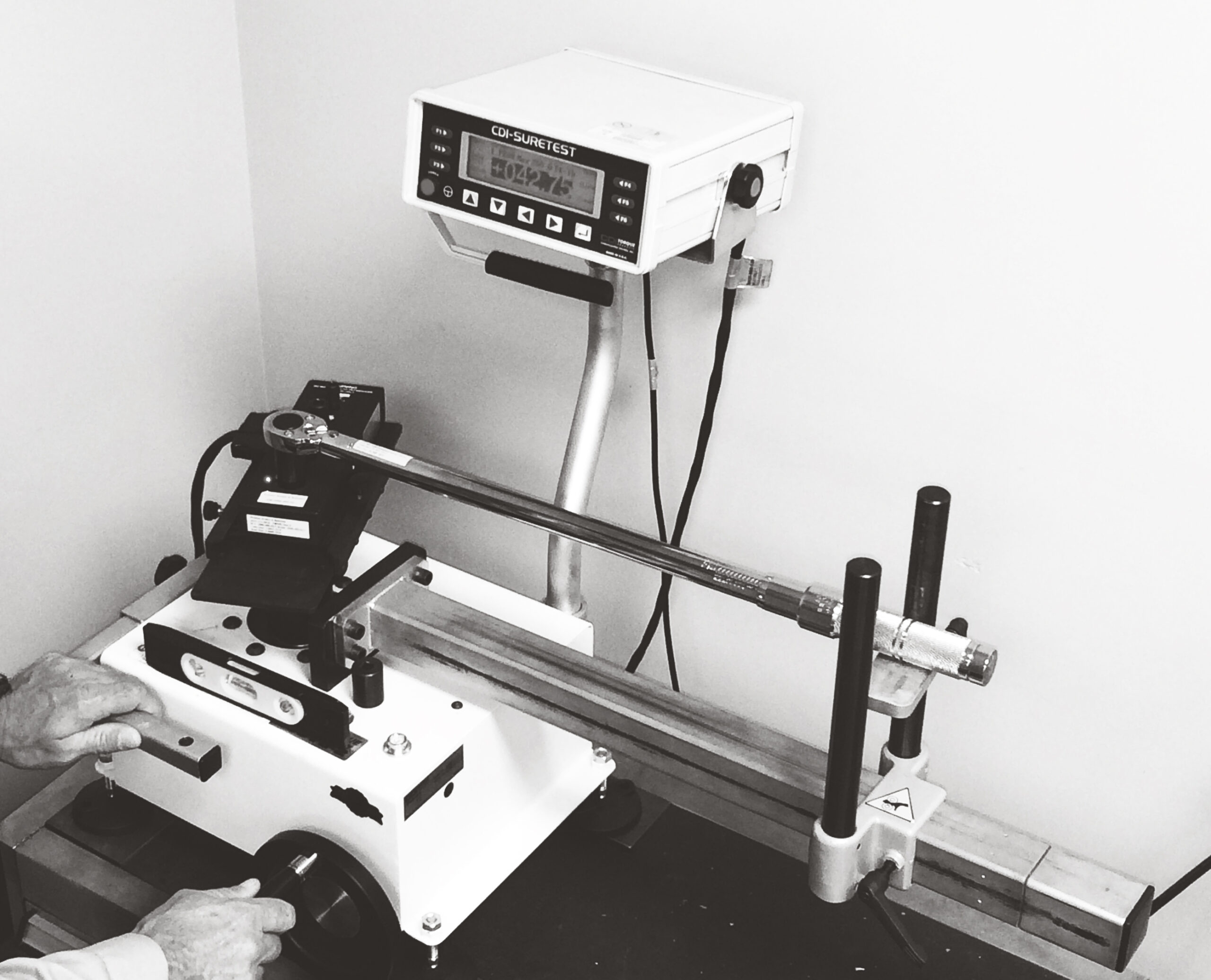

The Role of Calibration in Your Process

Calibration plays a quiet but critical role in nearly every production environment across industries from manufacturing to agriculture and beyond. Whether you’re weighing ingredients, tightening torque, or verifying fill levels, you rely on your equipment to deliver numbers you can trust. When those numbers drift, quality starts to slip. That leads to waste, downtime, and increased risks. Calibration is the simplest way to keep those risks in check.

What is Calibration?

Calibration is the comparison of a device against a reference standard with known accuracy and traceability. That comparison reveals how the instrument is performing today and whether it still meets the tolerances your process requires. This is where As Found and As Left data become especially valuable.

- As Found results establish a baseline measurement before any service is completed. These values help validate prior measurements and assess potential impact if the instrument is found to be out of tolerance.

- As Left results document device performance after service is completed. They confirm the instrument meets required tolerances and provide a benchmark for future measurements.

Together, these results provide a clear picture of equipment performance, indicate whether an adjustment was required, and establish traceability for measurements taken with the device going forward.

Calibration vs. Adjustment

These terms are often used interchangeably, but they serve different purposes.

- Calibration compares the measurement of an instrument against a known standard.

- Adjustment correction of error found in calibration.

Understanding the distinction helps teams make better decisions: calibration gives you clarity, while adjustment restores performance.

Confidence You Can Measure

A calibration is only as reliable as the standards and systems behind it. Accredited labs maintain certified, traceable reference standards that are routinely verified, ensuring each measurement can be trusted. ISO/IEC 17025 accreditation strengthens that reliability even further by requiring proven methods, trained personnel, and a documented quality system. These controls also help keep measurement uncertainty low, which means you receive results with the highest possible confidence and clarity. Together, these elements provide assurance that your calibration results are accurate, consistent, and ready to support any audit or regulatory review.

Calibration with System Scale

System Scale combines accredited calibration with the service mindset of an employee‑owned team. Our technicians understand how valuable uptime is, and that urgency shows in the way we operate. From our four‑hour response time to transparency and integrity while operating in your plant, our team’s values show in our work.. We support a wide range of equipment, including scales and precision instruments, and provide optional access

to CalVault, our secure online platform for storing and retrieving calibration certificates and equipment records. CalVault keeps your documentation organized and accessible so your team spends less time chasing paperwork and more time keeping production moving.

Ready for Reliable Calibration Support?

Whether you need a single service event or a calibration partner who can support your entire program, our team is here to help.

Request a quote to get started.